,Building a custom motorcycle is a hands-on journey that takes patience and creativity. In this project, Dan works with Crystal to transform her CB400 into a unique cafe racer or scrambler-inspired bike. They start by checking the bike’s condition and making a list of what needs to be fixed and changed, including cleaning the carburetors, replacing broken parts, and planning for more custom features.

Crystal, though experienced with riding, is taking on her first project bike and is eager to learn and be involved in the process. Together, they clean, repair, and upgrade parts, making sure each step moves them closer to building a bike Crystal can be proud of.

Key Takeaways

- The project begins with a full check and plan for modifications.

- Repairing, cleaning, and customizing key parts are early priorities.

- Teamwork and hands-on learning drive the project forward.

Project Overview

Crystal’s Custom Motorcycle Goals

Crystal wanted a motorcycle that matched her personal style and riding needs. She liked the scrambler look with knobby tires and a higher seat. She also preferred something with both a vintage feel and practical features for everyday use. Together, she and Dan talked through different ideas, making sure the design would fit her vision and give her a hands-on role in the build.

Key things Crystal wanted:

- Scrambler-inspired design

- Comfortable riding position

- A bike she could help build herself

Crystal had owned motorcycles before, but this was her first chance to help make one from the ground up.

Why the Honda CB400 was Chosen

After considering several motorcycles, they decided on the Honda CB400. The bike, although not perfect, offered a strong base and was in good enough condition for a custom project. There were some existing modifications on it, and a few minor issues like a broken speedometer and a small oil leak, but nothing that couldn’t be fixed.

Reasons for picking the CB400:

| Feature | Details |

|---|---|

| Engine | Reliable and well-known |

| Current Condition | Needed minor repairs and cleaning |

| Compatibility | Good for scrambler or cafe racer builds |

Some updates, such as Mikuni carburetors and racy design touches, made it even more appealing. The decision was sealed after a fair deal was made, leading to the start of this custom motorcycle journey.

Assessing the Starting Condition and Planned Changes

Review of Current Custom Work

- The fuel tank is not the original part. Its source is unknown—it may be custom or from a different motorcycle.

- There are modifications on the chain guard designed to give the bike a sportier style.

- The speedometer has a broken needle and needs to be changed.

- The handlebars will be swapped out because they do not fit the desired look.

- The front forks are in good shape, with no oil leaks or surface damage.

- The wheels are being considered for a change to a spoked design.

- The existing exhaust pipes are wrapped. These wraps will be removed to check the pipe condition before cleaning or re-wrapping.

- The bike has large air filters connected to Mikuni carburetors, which is considered the best improvement so far.

Table: Parts to Keep, Change, or Inspect

| Part | Action Planned |

|---|---|

| Fuel Tank | Replace or modify |

| Chain Guard | Update for style |

| Speedometer | Replace |

| Handlebars | Swap out |

| Front Forks | Keep as-is |

| Wheels | Consider spoke conversion |

| Exhaust Pipes | Inspect, clean, or re-wrap |

| Carburetors | Keep (Mikuni) |

Issues Found During Inspection

- Idle Issue: The engine could not hold a stable idle. Cleaning the carburetors and jets was needed to fix this.

- Oil Leak: A minor oil leak was present. It will be addressed as the work continues.

- Broken Speedometer: The speedometer needle is snapped, requiring total replacement.

- Cosmetic Wear: The motorcycle appears worn in some spots.

- Exhaust Wrap Condition: The wrap needs to come off to check for any hidden problems with the exhaust pipes.

- Welding Quality: Some welding on the bike was not tidy and will be improved for safety and appearance.

List of Key Problems:

- Idle not holding

- Slight oil leak

- Damaged speedometer

- Rust or old finish on wheels and rim

- Unappealing handlebars

- Poor welding on some frame parts

The wheels are now being separated, sandblasted, and painted. Paint was chosen over powder coating since baking powder coat can damage alloy rims, which is important with these Honda wheels.

Key Fixes and Improvements

Solving the Idle Problem

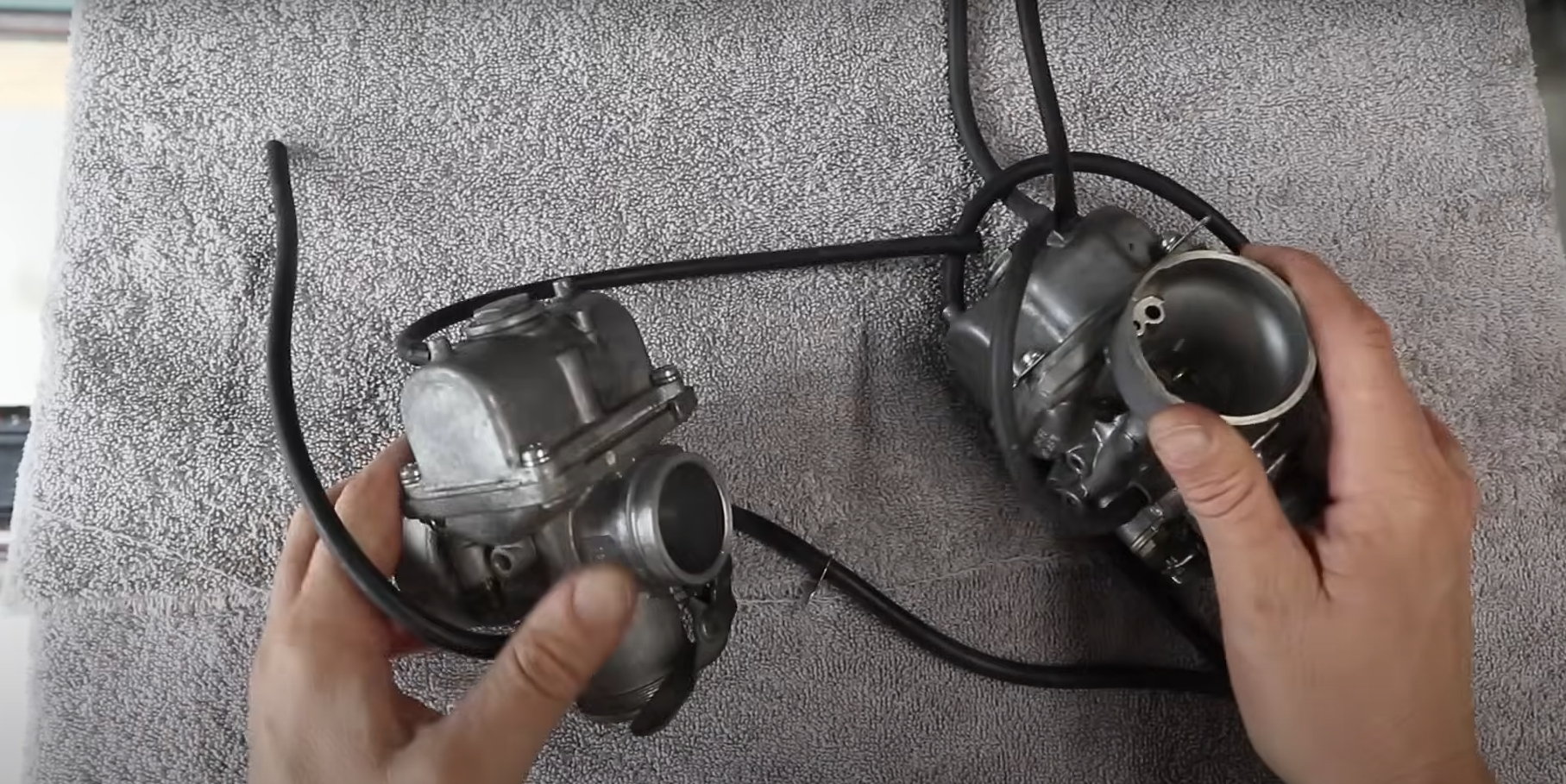

Getting the CB400 to idle properly was the first task. The engine started, but it would not keep running at low speed. The carburetors seemed to be the main cause of this issue. Cleaning and checking the jets helped get the idle working right.

Steps Taken:

- Removed the carburetors from the bike

- Inspected the jets for old fuel or debris

- Used fine wire and compressed air to clear any blockages

Deep Cleaning the Carburetor

The carburetors needed a thorough cleaning to run smoothly. An ultrasonic cleaner helped clean most parts. For stuck-on fuel inside the jets, a thin wire and compressed air were used to clear them out.

Helpful Tools and Tips:

- Ultrasonic cleaner with a general degreaser

- Set cleaner heat to about 60°C

- Use a small wire or brush to clear jets

- Compressed air to make sure parts are fully clean

Note: A sample cleaning solution gave even better results, but the exact product name is unknown.

Part Replacement and Freshening Up

Several parts needed attention or replacement. The broken speedometer was set to be replaced. Unwanted parts such as certain handlebars were removed by request. The rims were separated from the tires and sandblasted, then repainted for a fresh look, following advice not to powder coat certain alloy wheels.

Parts Worked On:

| Old Part | Action Taken | Reason |

|---|---|---|

| Speedometer | Remove and replace | Needle was broken |

| Handlebars | Swap out for new ones | Disliked old style |

| Exhaust wrap on pipes | Remove, inspect, repaint/rewrap | Clean look and protection |

| Rims | Sandblast and paint | Restore appearance, avoid powder coating on alloy wheels |

Crystal participated in tear-down and cleaning steps, learning as the work progressed.

Planning for Personalization

Design Elements and Options

Crystal expressed a strong preference for the scrambler style, aiming for a bike with chunkier tires and a higher seat. Together, a mix of ideas for the finish and overall look were discussed, focusing on making the bike fit her personality and riding style.

There was special attention to details with what to keep, what to swap, and what to modify. Some highlights:

- The original fuel tank was already replaced with a non-standard one, leading to questions about what style to go for next.

- Chrome chain guard and previous mods gave a sporty touch, but many parts were due for an update.

- Crystal disliked the current handlebars, so new options will be considered.

Table: Items Under Review

| Current Feature | Action Planned |

|---|---|

| Broken speedometer | Replace with new unit |

| Existing handlebars | Swap for new style |

| Tank (non-original) | Decide on new design |

| Exhaust wraps | Remove, clean, re-wrap |

| Spoked wheels | Discuss possibility |

Options for Modifying Components

Crystal will take part in working on the bike by learning basic mechanics and trying her hand at certain tasks. Both cosmetic and functional upgrades were considered, tailoring the process to her interests and the bike’s needs.

She prefers a scrambler appearance, so adding more aggressive tires and possibly altering the subframe are on the table. The wheels were sandblasted and painted instead of powder coated to avoid damaging the alloy. Cleaning and tuning the carburetors was a first priority to get the bike running right before anything else.

List: Main Modification Ideas

- Change current wheels to match the desired look and function.

- Update the exhaust system or restore its appearance.

- Refresh worn parts and remove anything Crystal dislikes.

- Adjust the frame for better comfort and unique styling.

- Involve Crystal in mechanics and choices, building her confidence as the project develops.

Step-By-Step Assembly Tasks

Taking Apart and Cleaning Parts

Crystal was ready to dive into hands-on work, so she learned how to use different tools for safe removal of motorcycle pieces. The starting point focused on detaching the carburetors. Each carburetor came off the bike, then was taken apart so the individual jets could be cleaned. An ultrasonic cleaner with a general-purpose degreaser, heated to about 60°C, worked to remove old fuel and grime from most of the parts. Some jets still had tough debris inside, so a fine wire and compressed air finished the job.

Getting Wheels and Tires Ready

One of the first major tasks was to remove the wheels and separate the tires from the rims. Crystal and her helper cleaned up the wheels and made sure all leftover grease was washed away. The front and rear wheels were taken off and new knobby tires were prepared for mounting to fit the scrambler style they aimed for. By focusing on the wheels early, the bike started to look more complete and provided motivation for the next parts of the project.

Methods for Fixing Up Rims

After taking off the tires, the rims needed more attention. The rims were brought to a sandblaster to get rid of old paint and stains. For these Honda alloy rims, they used paint instead of powder coating. Painting is safer for these wheels because the heat from powder coating can damage riveted alloy rims. Once clean and dry, the rims were painted carefully, giving the bike a fresh base to work from.

| Step | Tool/Method Used | Reason |

|---|---|---|

| Carburetor clean | Ultrasonic cleaner | Removes gunk and old fuel |

| Jet clearing | Wire & compressed air | For tough debris in jets |

| Rim prep | Sandblasting | Cleans & removes old paint |

| Rim finish | Paint (not powder) | Protects sensitive alloys |

Each process was done with care to avoid mistakes and to make sure the bike would be a solid base for custom work later.

Working Together and Gaining Experience

Crystal’s Role and Efforts

Crystal wanted to be a big part of building her motorcycle. She helped make decisions about parts and design, such as choosing styles she liked. For example, she helped pick if the bike would look more like a cafe racer or scrambler. Crystal was part of talks about changing things like adding spoke wheels, fixing the seat, and updating the handlebars.

She also helped with the work. She learned to use tools and tried jobs like cleaning and prepping the bike, expressed what she wanted changed, like removing certain parts she did not like, and jumped in to help clean and get the bike ready for the next steps.

Growing Skills While Building

They tackled a few challenges as they fixed up the motorcycle. Some steps they worked through included:

- Taking off and cleaning the carburetors

- Figuring out why the engine would not idle

- Fixing parts that were not working, such as the broken speedometer

Crystal got to learn new skills as she worked on the project, like how to clean engine parts and how to spot problems. She asked questions, learned by doing, and practiced taking things apart and putting them back together. The project gave her a chance to try welding, degreasing parts, separating tires and rims, and understanding new tools and cleaning supplies.

Key Skills Practiced:

| Task | What Crystal Learned |

|---|---|

| Cleaning parts | How to use an ultrasonic cleaner |

| Fixing mechanical problems | Spotting and clearing fuel blockages |

| Removing and replacing parts | Using tools for motorcycle repair |

Wrapping Up and Moving Forward

The bike now runs and idles smoothly after cleaning the carburetors and jets, even using a new cleaning solution that brought impressive results. Some parts were removed and cleaned, including an old tank and broken speedometer. The rims and tires have also been updated, and the wheels were painted instead of powder coated to protect the alloy.

Next steps include:

- Giving the bike a full clean and degrease.

- Beginning the main teardown for further custom work.

- Welding and fixing previous poor welds to improve structure and appearance.

- Replacing unwanted parts, like the disliked handlebars and broken speedo.

Crystal is keen to be involved in the process, using tools and learning hands-on skills along the way. Input and feedback from viewers are encouraged, as more updates will follow as the project continues.

| Task | Status | Notes |

|---|---|---|

| Carb clean | Done | Bike now idles properly |

| Tire/rim work | In progress | Painted to avoid overheating |

| Teardown | Upcoming | Next major phase |

| Welding fixes | Upcoming | Improve previous work |