Today’s feature is about a different breed of Z. It’s a totally revised and, for lack of a better term, ‘grown up’ version of a Honda Z50A. Built by Z expert David Morales this is the Davmomoto “50 Magnum” and here’s the story of how it came to be…

“My name is David Morales and I build bikes under my Davmomoto brand out of Denton, Texas. I have a long history of metal work, from steel sculpture to jewelry, custom musical instruments and boutique electronics. I have building motorcycles seriously for the last 10 years, working out of a custom built workshop in my backyard. I have mostly simple hand tools but also use a sheet-metal brake, shear and roller, TIG, MIG, plasma cutter, and the usual assortment of drill presses, sanders, and grinders to get each job done. There are over 50 bikes in the workshop right now, but most of them are small displacement models which I seem to favor. I have built somewhere around 20 custom bikes, and plenty of straight-up restorations, mostly of 70’s small Hondas. I left my day job of 30 years (medical diagnostic ultrasound) a year ago, and since then have been building bikes in earnest, with about six done over the last year.”

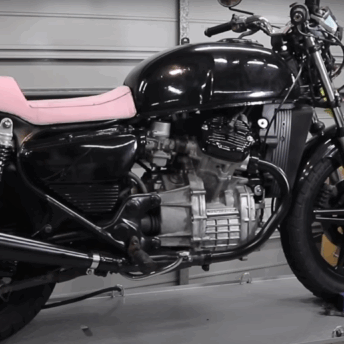

“This custom is based on a 1969 Honda Z50A and took place over 7-8 months. I built it for myself to take on the challenge of stretching one of these frames and overcoming some of its “shortcomings” in the process. The idea behind stretching the Z50A frame was to allow for bigger wheels and tires, to make more room for things like a bigger carburetor and so that I could change out the head tube and install some real front forks.

My concept was to create an adult sized Z50 with better brakes, suspension, ergonomics, and of course more power. Some of the outside design influences were obviously café racers, but also a little bit of streetfighter style. The concept also included the installation of a mountain bike shock under the seat to make the original hardtail setup a little less punishing.”

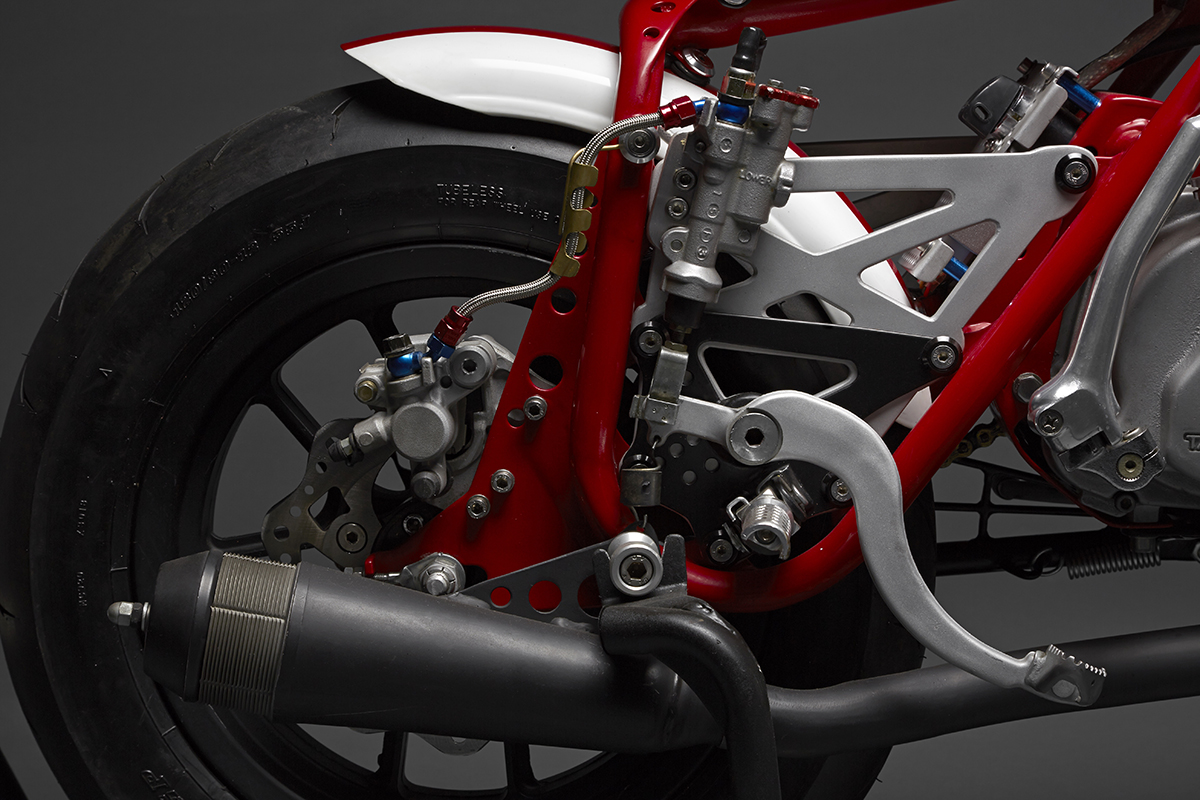

“The first stage of the build was to completely disassembled the frame into a number of small pieces. Using an inner sleeve along the entire length of the tubes, they were extended to make the height of the frame 2 inches taller, and the length 4 inches longer. I also welded in a number of gusset plates into locations that are common damage points on these original frames. I also constructed aluminum torque plates to fit inside the rear frame loops to stiffen the tubes, as well as creating a place to mount the rear sets.

Next the custom seat and the assembly which uses a Fox float mountain bike shock was put together. The tank was extensively modified with the lower portion of it cut off and knee dents pounded into the sides. The front fairing was made from a wire form before being hand laid in fiberglass and uses the visor is from a Ducati 956. The rear fairing is made of steel and the taillight assembly was also made from scratch.”

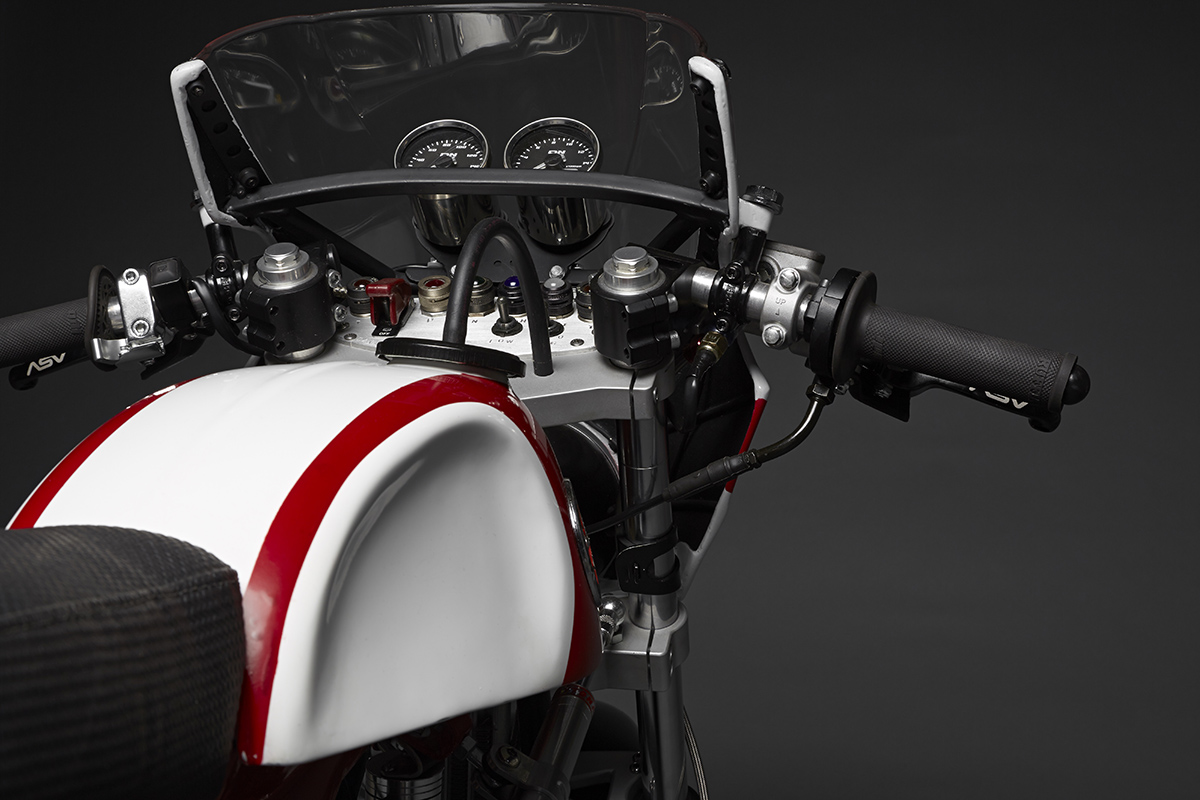

“I built a custom electronics panel in the front of the bike ussing WW2 era aircraft instrument lights which all runs off a custom wiring harness. The front lower fork brace is made from aluminum billet to match the rear plates and the pipe was also custom made using a supertrapp muffler.

I completed all the fabrication, engine work, bodywork, paint, electrical and assembly work myself. The only thing that was done by someone else was the stitching of the seat cover which I had made to fit the foam and seat pan I built for the bike.”

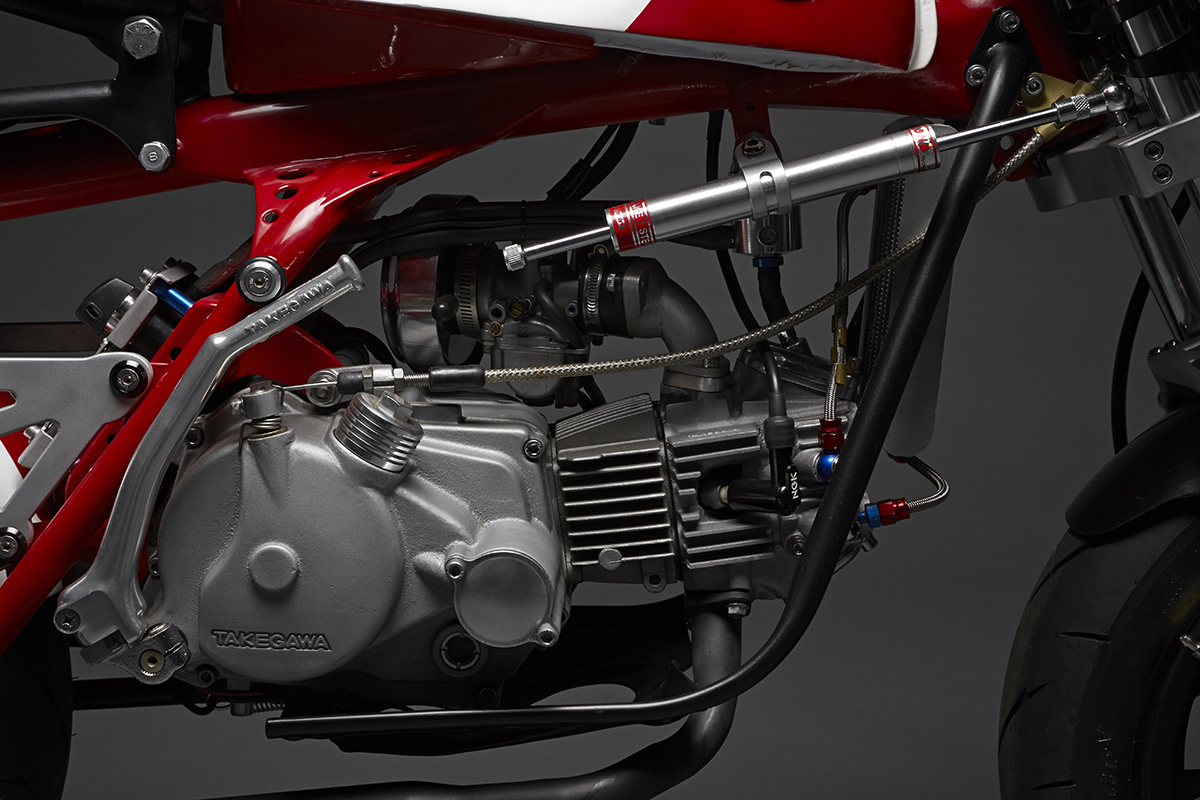

“One of the details I was particularly proud of was the lowered gear shifter assembly. It used parts that I reclaimed from a busted transmission gear and allowed the normal shifting pattern to be used, as well as moving the tip of the shifter to a more usable location.”

BUILD SHEET:

- Billet triple tree set-up from HondaTB

- Honda NSR50 forks

- Rear suspension Fox float mountain bike shock

- Four pot Brembo brake on the front and the rear is from a CRF 250 with CRF 450 masters

- Wheels are NSR 50 knockoffs with Dunlop TT 92’s

- Engine uses cases from a CRF50 bored out to allow for a 124cc top end

- Takegawa roller – rocker four valve head and jug

- Takegawa 5 speed transmission and special clutch

- Yoshimura TMJ 28 carb and intake

- Woodcraft clip-ons with ASV levers

As with most build stories there’s a lot more to it than what David has been able to explain here. If you’d like to see how the 50 Magnum came together step by step you can read the extensive build thread here on Planet Minis.

Honda’s minuscule Z series motorcycles have enjoyed huge success since their inception some 50 or so years ago. Everything about the tiny little motorcycles defies common sense. From their sub 22-inch seat height to the ridiculous riding position you have to assume to pilot one (hence their nickname of Monkey or Gorilla bike). The fact that Honda still produces the Z today, and that they can be registered and ridden legally on the road is mind-boggling, but there’s one thing that no one can deny, they’re an absolute hoot to ride!